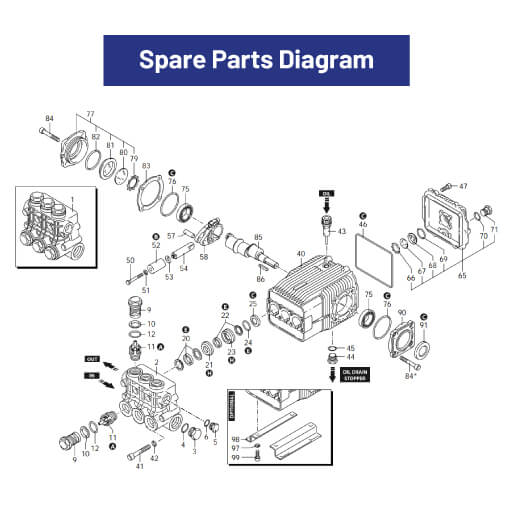

3-piston alternating volumetric pumps for use on cleaning units and industrial systemsCan be coupled to various types of motors, directly or with flexible joint. Pump body and cover in die-cast aluminium alloy. Side cover may be blind or incorporate oil sight glass. Rear cover with oil drain outlet and sight glass. Pistons driven by crank-connecting rod mechanism. Pump shaft in pressed high-strength steel. Oversized friction bearings. Connecting rods in die-cast special low-friction zinc-aluminium alloy. One-piece ceramic pistons. Pump head in pressed brass. Double gasket sealing system. Intake and delivery valves have plugs for easier maintenance.

Features and Benefits:

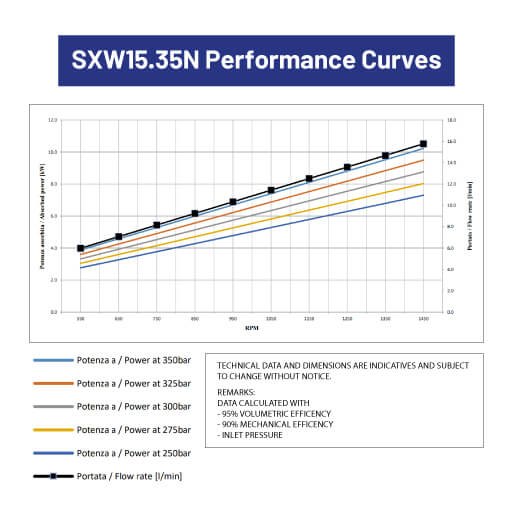

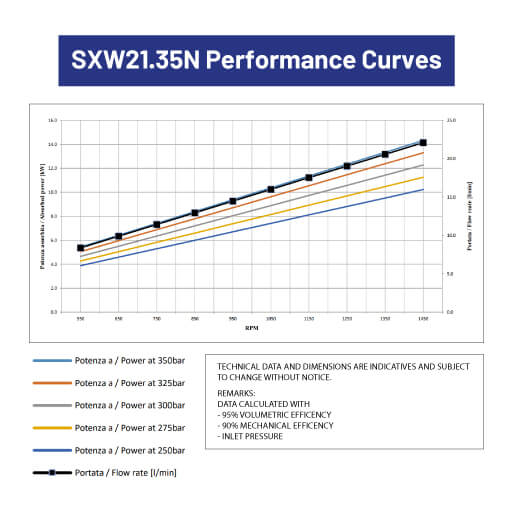

- Generate significant pressure, ranging from 1,000 to 5,000 psi, allowing them to tackle demanding tasks.

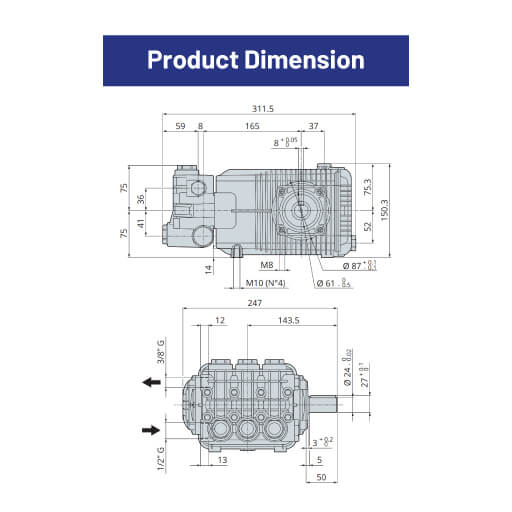

- Compact Size and Lightweight: Easier to handle and install compared to other high-pressure pumps, especially beneficial for space-limited or portable applications.

- Durable Construction: Built to withstand harsh conditions and heavy-duty use, typically made from high-quality materials like stainless steel or cast iron for long-lasting performance.

- Corrosion Resistance: Designed to be resistant to corrosion, making them suitable for use with harsh chemicals, saltwater, and other corrosive substances.

- Wide Range of Configurations: Available in various configurations with different flow rates, pressure ratings, and port sizes to meet specific application requirements.

- Customizable: Sold without a motor or housing, allowing for greater flexibility for customization and integration into existing systems or custom setups.

Customized Standard Accessories:

- 1 x Mecline regulating unloader valve

- 1 x Mecline safety valve

- 1 x WIKA pressure gauge (Stainless Steel Body)

- 1 x High pressure hydraulic hose (15 meter 3/8″ R2)

- 1 x 0°-35 S/S Nozzle or 0°-45 S/S Nozzle

- 1 x Mecline 45″ High pressure gun